Broken Leaf Springs - What Causes Leaf Springs To Fail?

Ever have a leaf spring crack, become fatigued or break, and wonder what the cause is? In this article, we take a look at a few common reasons why leaf springs fail. If you are having issues with your suspension and believe it is your springs, be sure to check out our leaf spring troubleshooting guide. If you are replacing leaf springs, but need help determining how to measure them, or need help identifying them, take a look at how to measure leaf springs for some good tips and guidance.

Loose U-Bolts

This image shows a leaf spring with center bolt failure. Leaf spring center bolts shear, or break when the u-bolts are not properly torqued (not tight enough). U-bolts should be checked periodically to verify they are tight - this is especially true after installing new truck springs . In our leaf spring repair shop, we recommend customers return to have u-bolts inspected, and re-torqued after 500 miles of driving on new leaf springs. Even if you have a professional installer install springs on your truck, you should always inspect your u-bolts to make sure they haven't come loose.

Corrosion and Fatigue

Corrosion and fatigue are typically caused by a combination of time and the elements. Numerous variables will impact on how long your leaf springs will last before they suffer from corrosion or fatigue. The amount of weight you haul, the part of the country you live in, the roads you drive on, etc will play a role in the life of your springs. In Michigan, drivers are well aware of the March-April thaw, and the impact pot holes have on their suspension - this is especially true for commercial trucks. If you use your truck on salted roads, or in environments where there are corrosives involved, spraying the corrosives off the springs will help prevent premature corrosion.

Overloading Your Truck Springs

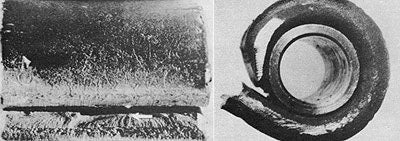

Everyone says they never do it , but we see it all the time. Overloading is pretty self-explanatory. You put more weight in the back of your truck or you are towing a load heavier than what your truck is rated for by the manufacturer. We all love to do it, but the negative effect on your truck springs is unavoidable. The left image shows the radial shear marks from an overloaded spring. The image to the right shows distortion of the spring eye from overloading.

Overload Kits - Suspension Air Bags and Helper Springs

How do you prevent overloading your truck springs? Obviously you could carry less weight or purchase a truck with a higher weight rating. If buying a new truck or hauling less weight is not an option, you could add an overload kit like a suspension air bag kit, or adding a set of helper springs. Overload kits are designed to take some of the weight off the leaf springs and place it onto the overload kit, however, they will not allow you to increase the GVWR of your vehicle. At TruckSpring.com, we carry a number of different options to meet your requirements and budget.

Increase the Spring Pack - Add a Leaf

Another option that is more popular with commercial vehicles it to add another piece of steel to the spring pack. This may cause the ride to be stiffer, but if you are always hauling heavier loads in a commercial setting, this may be your best bet.

We do not recommend adding a new piece of steel to leaf springs that already suffer from fatigue. You are better off replacing both of your truck springs with new ones with a higher weight rating. It's very common that we will have someone only want to replace one busted leaf in a spring pack and a few months later a different leaf breaks. If one has cracked, the others are probably in the same condition and will likely not last much longer.

Weld splatter is more common in commercial trucks and vans that come from the factory without a bed, or on motorhome leaf springs . This is caused by welding a body or accessories to your truck in the same area as your leaf springs. Just a small amount of weld spatter can be disastrous to the life of your spring. About the only way to prevent this is to inspect your springs after the body has been installed, to make sure no one was careless with the welder.

We've discussed a few common reasons why leaf springs break, sag, and fatigue. There are other manufacturing reasons such as quench cracks, tight eyes, notches, incorrect temperatures, etc. that can cause failure. However, in today's modern, high-tech manufacturing processes and quality control, manufacturing defects are not nearly as common as they were in the past.

If you have any questions about your leaf springs or need replacement leaf springs, call Michigan Truck Spring at 1-800-358-4751. We carry OEM replacement leaf springs for all vehicle makes and models, from old corvettes to semi trucks and trailers.