When upgrading to a bigger trailer, a new tow vehicle, or just replacing an old trailer brake controller there are a few features to consider that may make your towing experience more enjoyable and safer. All brake controllers are wired into the vehicle with the same 4 wire setup but the technology inside the controller is what sets different models apart.

Why do I need a brake controller?

Brake controllers are the physical link between your brake pedal on your vehicle and the brakes on the axles of your trailer. Without them, uncontrolled weight can push forward, creating the potential for accidents and damage, not only to your truck or car but other vehicles if you can’t slow or stop in time. An electric trailer brake control provides power from a towing vehicle to the electric brakes on a trailer. If your trailer has electric brakes, a brake controller is needed. Always check your tow vehicle owner’s manual. What you can tow, including weight and number of axles, is important in helping you make the right decision about what brake control you will need.

While there are many styles, there are only two types of brake controls, time activated and proportional.

Proportional Brake Controllers

Proportional controllers are the type most consumers purchase if they:

- Tow frequently, especially trailers used to transport heavy loads.

- Move precious cargo, like your friends and family, horses, livestock, racing vehicles, etc.

- Have a fleet of trailers and need to quickly switch from one tow vehicle to another.

Most proportional brake controllers are designed with the industry standard ‘plug-n-play’ which allows for quick and easy interchange with compatible vehicles. With proportional controllers every action of your brake pedal in the tow vehicle is matched, precisely and smoothly. When you slow for a railroad grading or go down a steep hill, your trailer eases down and matches your speed mile by mile.

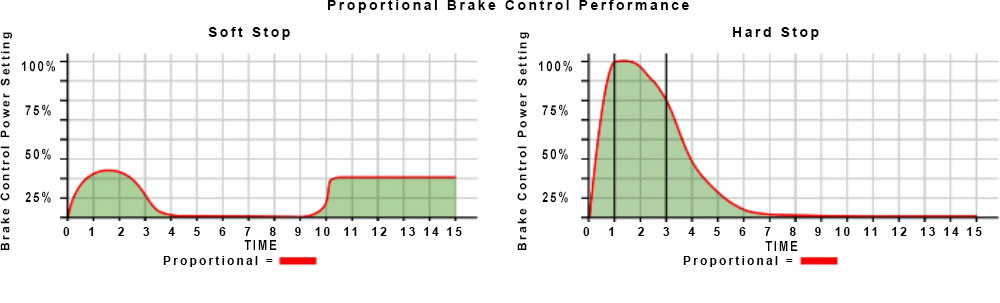

(In the graph above, the red line shows what happens when you brake in your tow vehicle, and what happens to the brakes in your trailer (blue line) when a proportional controller’s installed. It’s an exact match. Smooth and even response, second by second. It’s why these systems have become the choice of most consumers.)

Proportional brake controls determine the tow vehicle’s rate of deceleration and apply the trailer brakes to match. They provide smooth braking response in any stopping situation, with no need for adjustments.

Pros of Proportional Brake Controllers:

- Safety: In an emergency stop the proportional controller will match the braking power instantly instead of ramping up.

- Decreased Brake Wear: With tow vehicle and trailer braking the same brake wear is even.

- Smooth Braking: With the trailer matching the tow vehicle there is no jerking when the trailer brakes apply.

- No Adjustments: No need to adjust the brake control for different size trailers or road conditions.

Cons of Proportional Brake Controllers:

- Mounting: Most must be in line with vehicle direction, so, that limits space where they can be installed.

- Cost: Advanced technology adds to the bottom line of your up front expense.

Time Delay Brake Controllers

Time delay trailer brake controllers apply the trailer brakes with a preset amount of braking power and there is a delay as the unit ramps up the power to full braking. On most models the time and the initial braking power is adjustable. Time delayed systems slow your trailer using preset brake settings and on how long your foot’s on the brake. The biggest difference is braking isn’t instantaneous.

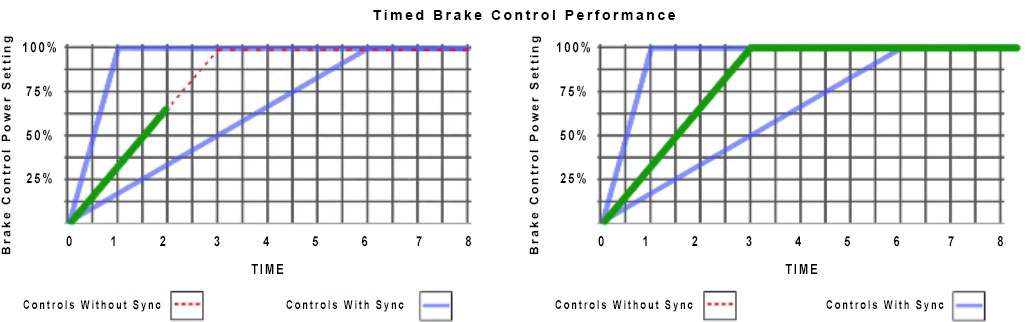

The graph above shows what happens with a time-delayed brake controller. The controller is preset before hauling a load, based in part on the weight of your trailer. There is a delay from when you begin slowing (red line) to when the power levels build up in the trailer to compensate (blue line).

Time activated brake controls apply braking power at a fixed rate of time that is NOT proportional to the pressure you apply to your brake pedal. They provide voltage output that increases the gain setting over a period of time (typically 3 seconds). This is known as the ramp cycle.

Pros of Time-Delay Brake Controllers:

- Cost: If you don’t tow often your initial expense is much less. Great if you tow a small trailer for moving a few things, snowmobiles in the winter, lawn equipment, etc.

- Installation: Can be mounted in any location on the tow vehicle and in any position.

Cons of Time-Delay Brake Controllers:

- Wear: Uneven pressure between tow and trailer means higher wear on brakes over time.

- Feel: Improper settings for initial brake pressure could create ‘jerking’ between tow and trailer.

- Brake Pulse: As soon as hazard lights are on, trailer brakes can ‘pulse’ on and off potentially damaging brake magnets over an extended period.

PROPORTIONAL: vs TIME-DELAYED:

Smooth braking Same braking power, no matter conditions

Designed for all load types For lighter, occasional towing

More expensive Less expensive

Less wear on brakes over time More wear on brakes over time

Best on all road conditions Not recommended for steep hills or valleys

Even braking, between tow and trailer Tow vehicle carries most of load in braking

All brakes controllers have their advantages and what type and features in a brake controller you'll need is typically determined by what you are towing and how often. Feel free to contact us at 1-800-358-4751 or 989-755-0561 if you have any questions about which trailer brake controller is the correct fit for your towing setup.