Periodically inspecting your suspension air bags can increase their life and make operation safer. Luckily, there are nine easy steps to making sure that your air springs are undamaged and operating correctly. These steps can be taken while the vehicle is in for periodic maintenance. The total inspection takes a matter of minutes to complete. Finding and correcting problems with your air springs before you hit the road will save you time and money.

Periodically inspecting your suspension air bags can increase their life and make operation safer. Luckily, there are nine easy steps to making sure that your air springs are undamaged and operating correctly. These steps can be taken while the vehicle is in for periodic maintenance. The total inspection takes a matter of minutes to complete. Finding and correcting problems with your air springs before you hit the road will save you time and money.

- Inspect the outside diameter of the air spring. Make sure to check the bellows for signs of irregular wear or heat cracking.

Inspect the airlines to make sure there isn’t contact between the air line and the outside diameter of the air spring. While in operation, contact between these parts can create friction and rub holes in the spring very quickly.

Inspect the airlines to make sure there isn’t contact between the air line and the outside diameter of the air spring. While in operation, contact between these parts can create friction and rub holes in the spring very quickly.- Ensure that there is sufficient clearance around the total circumference of the air bag while it is inflated to its maximum size.

- Look for debris buildup around the air bag's piston. The piston is the bottom component that plunges the air from the bellows on reversible sleeve style air bags.

- Make sure the correct ride height can be maintained. Any vehicle featuring air bags have an established ride height specified by the original equipment manufacturer. The ride height should be specified in the vehicle’s service manual. Make sure that the ride height is within ¼ inch of the specified height. This measurement can be taken while the vehicle loaded or empty.

Inspect, clean, and if necessary, replace leveling valves or height control valves. These valves play a large part in ensuring that the total air spring system works as required.

Inspect, clean, and if necessary, replace leveling valves or height control valves. These valves play a large part in ensuring that the total air spring system works as required.- Make sure your shock absorbers and end connectors are not worn or broken. Be on the look out for leaking hydraulic oil, as this can be a sign that your shocks are damaged. If this is the case, you must replace your shock absorbers immediately. Your air bag can overextend and become damaged if the shock absorber does not limit its rebound.

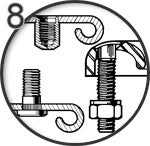

Check all mounting hardware to make sure that they are tightly fastened. If nuts and bolts are loose, you should re-torque them to the tightness specified by the manufacturer, being careful to not over tighten.

Check all mounting hardware to make sure that they are tightly fastened. If nuts and bolts are loose, you should re-torque them to the tightness specified by the manufacturer, being careful to not over tighten.- Clean the air spring with the approved cleaning products, such as soap and water, isopropyl alcohol, ethyl alcohol, and methyl alcohol. Non-approved cleaners include abrasives, open flames, all organic solvents and direct pressurized steam cleaning.

Important: Never service the air suspension on a truck or trailer with the air springs inflated.

Firestone Air Bags and Air Spring Kits

- Firestone Coil Rite Air Springs for Coil Spring Suspensions

- Firestone Sport-Rite Air Helper Springs

- Firestone Ride-Rite Air Helper Springs for Leaf Spring Suspensions

- Firestone Level-Rite Air Spring & Damper

Firestone Air Bags for Light Duty Trucks, Pickups and SUVs

Firestone Air Springs for Buses

- Single Convoluted Bus Air Springs

- Double Convoluted Bus Air Springs

- Reversible Sleeve Bus Air Springs

Firestone Air Springs for Heavy Duty Trucks and Trailers - Class 6, 7, 8

- Reversible Sleeve Air Springs

- Single Convoluted Air Springs

- Double Convoluted Air Springs

- Triple Convoluted Air Springs

Replace your worn and damaged air bags with Firestone Air Bags and Replacement Air Springs from Truckspring.com, your source for truck suspension parts. Call Michigan Truck Spring 1-800-358-4751 if you have any questions about Firestone air springs. They have been installing them for years and are authorized warehouse distributors for Firestone air springs and air bags.